Technical Specification

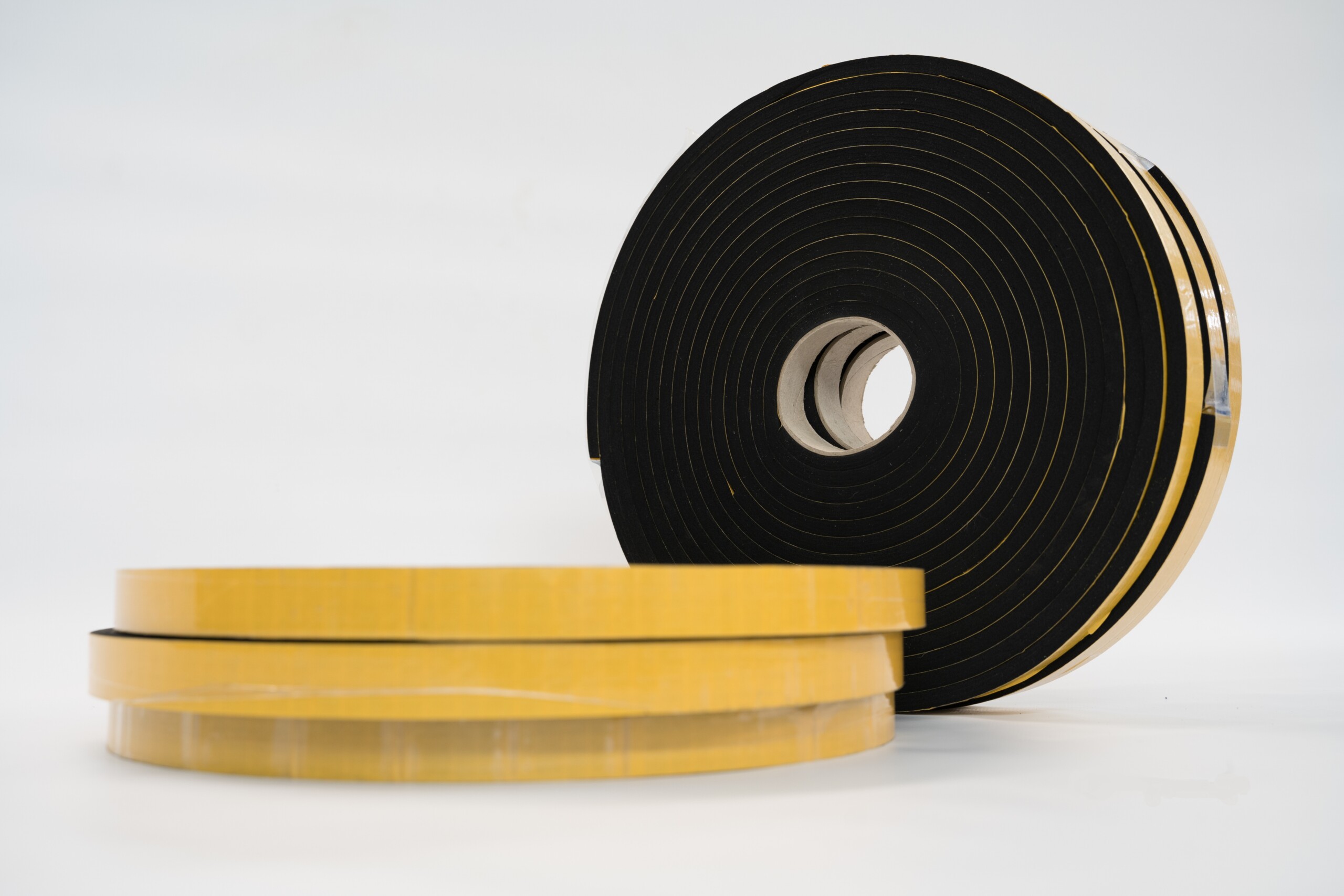

| Thickness | 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 11mm |

|---|---|

| Compound | EPDM/CR |

| Compression @ 25% Deflection (kPa) | Typical: 43 (ASTM D1056-00 spec limits: 35 to 65) |

| Compression @ 50% Deflection (kPa) | Typical: 112 (ASTM D1056-00 spec limits: 80 to 160) |

| Density (kg.m3) | 120 (ISO 845-95) |

| Compression set (50% 22h 20C) typical | 19.1% (ASTM D1056-00 spec limits: 25% max) |

| Water absorption, max. change in weight (%) | 0.8 (ASTM D1056-00 spec limits: 10) |

| Heat ageing, change in compressoin deflect0in, 168 hrs @70C | PAS (spec limits: +/- 30%) |

| Flammability | PASS (UL94 HBF) |

| Tensile Strength KN/m2 | >500 (ISO 1798-7) |

| Elongation at break % typical | >180 (ISO 1798-7) |

| Temperature range | -40 to +70C |

| Hig intermittent temperature | +100C |

| Resitance to Air and UV | EXCELLENT |

| Resistance to oil | POOR |

| Resistance to acids | GOOD |

| Environmental protection | CFC and HFC FREE/ CAN BE RECYCLED |

| Colour | Black |

| Specification ASTM D1056-00 AFNOR 99-211 | 2A2, B2C 2C08/3C08(squared) B3 C2 |

Please Note: There is a tolerance of +/-5% for all sizes of rubber sheeting, rubber matting and sponge rubber products.